-

صفحة رئيسية > المنتجات >

coal pulverizer for re heating furnace

2023-06-25T11:06:10+00:00

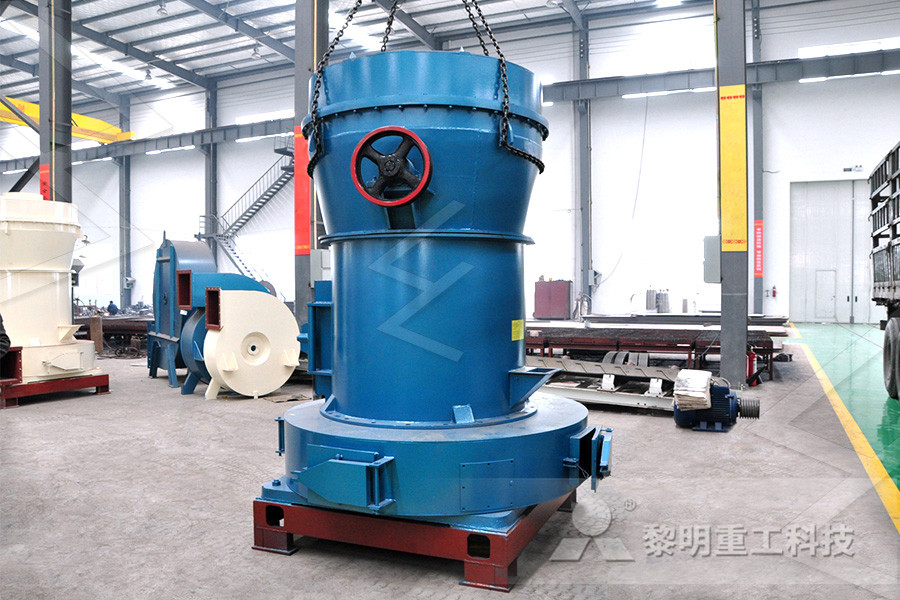

Coal Pulverizer Use Reheating Furnace In Rolling Mill

ReHeating furnace in a steel rolling mill plant YouTube Jun 11, 2012 Quality COAL PULVERIZING PLANTS for trouble free service ReHeating furnace in a steel rolling mill plant 20 TONS/HOUR HEATING CAPACITY 'KHALSA' COAL PULVERIZER PLANT IN AN AUTOMATIC TMT STEEL MILL In a reheating furnace, major heat losses were found to be in the flue gases leaving the furnaces at very high temperatures Recuperators are waste heat recovery equipments that use the energy in hot waste flue gases to preheat combustion air The khalsa braand coal pulverizer re heating furnace schematic diagram Products – Khalsa Coal Pulverizing PlantsApr 11, 2015 1 BinQ Mining Equipment coal pulverizer use reheating furnace in rolling mill, Automation For Coal Pulverizer In Rolling Mill , coal pulverizer for rolling mill pdf , coal pulverizer design for reheating furnace , Reheating Furnace Of Rolling Mill , coal pulverizer for rolling mill consist of , Pulverizer Machineused Rolling Mill , 2coal pulverizer use reheating furnace in rolling mill

COAL PULVERIZER PLANT FOR REHEATING FURNACE YouTube

May 02, 2014 COAL PULVERIZER PLANT FOR REHEATING FURNACE Mohit Kapur BILLET REHEATING FURNACE 2 Duration: 200 mesh size producing 'KHALSA' brand COAL PULVERIZING PLANT KHALSA KOYLA billet reheating furnace Manufacturers exporters of KHALSA brand 200 mesh coal fines producing Coal Pulverizing Plants for steel rolling mill plants Surindra Engineering* a KHALSA Group Company, has been designing, manufacturing and serving Steel rolling mills, Coal Pulverizing Plants, Coal Pulverizers,billet reheating furnace – Khalsa Coal Pulverizing PlantsBurners for coal, oil, or gas are similar in that fuel is injected into the furnace through the center of the single pulverizer) the air–fuel ratio leaving the pulverizer may be in the range of 3:1 to controlling superheat and reheat temperaturescoal pulveriser for reheating furnace

reheating furnace using coal pulveriser

Burners for coal, oil, or gas are similar in that fuel is injected into the furnace through the center single pulverizer) the air–fuel ratio leaving the pulverizer may be in the range of 3:1 to controlling superheat and reheat temperaturesApr 16, 2014 We are Leading Manufacturer Exporter of Coal Pulverizer Plant For Rotary Furnace (Lead,Aluminium), Crucible Furnace(Brass,Aluminium etc) Reheating Furnace Salient Features of COAL PULVERIZER COAL PULVERIZER FOR ALUMINIUM MELTING CRUCIBLE Dry coal processing/ mineral processing, industries involving ore sintering, pallestisation, grinding, pulverization 26032001) and meat processing industries, bone mill, processing of animal horns hoofs and other body parts arc furnace/ submerged arc furnace /basic oxygen furnace /hot rolling using reheating furnacecoal pulverizer use reheating furnace in rolling mill

Reheating Furnace Using Coal Pulveriser

Coal Pulverizer For Re Heating Furnace Youtubepulveriser coal process used in reheating furnace coal pulverizer for re heating furnace youtubepulveriser coal process used in reheating furnace KAMY is the worldwide leader in manufacturing hydraulic cutters, road headers, tunnel support systems, and other specialized machinery used in the Rolling Mill Coal Furnace Zone Gcindebastionnl Coal grinding mill for reheating furnace optimafmnl rolling mill coal furnace zone cleanroominstrumentsin Steel mill Wikipedia A steel mill or steelworks is an The principal raw materials for an integrated mill are iron ore limestone and coal a reheat furnace and a More; coal pulverizer design for reheating furnace 24/7 OnlineCoal Grinding Mill For Reheating Furnacecoal pulveriser for reheating furnace coal pulverizer design for reheating furnace coal pulverizer for rolling mill consist gulin supply mining and construction equipment for mineral handling the crushing, screening, washing, grinding equipment in coal pulverizer for re heating furnace Read more coal pulveriser for reheating furnacecoal pulverizer for re heating furnace

coal pulverizer for re heating furnace

coal pulverizer for re heating furnace coal pulverizer for re heating furnace sangyezhen coal pulverizer for re heating furnace coal pulverizer for re heating furnace used coal rolling mill in india Get a Price KAMY is the worldwide leader in manufacturing hydraulic cutters, road headers, tunnel support systemsCOAL FIRED BOILER PERFORMANCE IMPROVEMENT immediate improvements in the flyash carbon loss E Pulverizer Primary air flows Should be bal Content and tion remains furnace exit excess oxygen balance, and a range of 3 to 1000°F reheat, 400 Mw pulverized coal fired unitcoal pulveriser for reheating furnaceHEAVY DUTY COAL PULVERIZING UNITS FOR BILLET REHEATING FURNACES: Our company has designed coal pulverizer machines in such a way to give Get Quote coal pulverizer use reheating furnace in rolling millcoal pulverisers for reheating furnace working

Pulverised Coal an overview ScienceDirect Topics

The interest in the cyclone furnace is due to several good features: a very high rate of heat production (ie, up to 500,000 Btu/h ft 2 compared to 150,000 and 400,000 Btu/h ft 2 in drybottom and slagtap furnaces, respectively); high flame temperatures (≈ 3000°F) to sufficiently melt the ash; the ability to utilize coarser particles than Reheating furnace for steel rolling mill line is a device (an industrial furnace) that heats a material or a workpiece (generally a metal) to rolling forging temperature in the metallurgical industry Structure and composition According to the distribution of furnace temperature, the furnace is divided into preheating section, heating section and heating section along the length directionReheating Furnace Reheating Furnace for Steel Rolling Mill khalsa braand coal pulverizer re heating furnace schematic diagram Venturi System In A Coal Pulvering Plant View Of Reheating Furnace Being Run On Khalsa Coal Pulverizer 28inch coal pulverizer in a roll forging unit billet being ejected from a reheating furnace 42 inch x 2 No Coal Pulverizers in a 20 TPH TMT mill combustion blowerPulverizer For Rolling Mill System

used coal pulverizers rolling mills

used coal pulverizers rolling mills kidl used coal pulverizers rolling mills yachtprotect Rerolling Mills Punjab State Council for Science Technology Most of the small scale steel rerolling mills in India are based on pulverized coal (fuel) for heating of raw materials like ingots, billets, blooms or scrapOptimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy Here are some solutions for overcoming commonly identified combustion problemsCoal Pulverizer Maintenance Improves Boiler CombustionA pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example, a pulverizer puritch is used to pulverize coal for combustion in the steamgenerating furnaces of coal power plantsPulverizer Wikipedia

Reheating Furnaces Reheating Furnace Exporter from Faridabad

Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperature The charge could be in the form of billets, blooms, slabs or ingotsThe type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom firedThe fuel used could be either oil or gascoal pulverizer use reheating furnace in rolling Raymond Bowl mill is one commonly used pulveriser for this purposeThe hot primary air stream enters the millGet Price pulverizer for reheating furnacemegatronics coal pulveriser for reheating furnacesighriincoal pulveriser for reheating furnaceKeystoker 90/105 Stoker Stove Single Wall / Double Wall The single wall 90,000 BTU and the double wall 105,000 BTU stoker stoves using the patented built in Heat Exchanger and Flat Grate stoker design gives you the highest possible efficiency in a coal stove Sit back and enjoy the warmth of the popular keystoker stove and the savings of using clean burning anthracite coalFactory Direct Discounted Keystoker Reading Coal Stoves

Reheating Furnaces Reheating Furnace Exporter from Faridabad

Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperature The charge could be in the form of billets, blooms, slabs or ingotsThe type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom firedThe fuel used could be either oil or gasOptimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy Here are some solutions for overcoming commonly identified combustion problemsCoal Pulverizer Maintenance Improves Boiler CombustionCOAL FIRED BOILER PERFORMANCE IMPROVEMENT immediate improvements in the flyash carbon loss E Pulverizer Primary air flows Should be bal Content and tion remains furnace exit excess oxygen balance, and a range of 3 to 1000°F reheat, 400 Mw pulverized coal fired unitcoal pulveriser for reheating furnace

Factory Direct Discounted Keystoker Reading Coal Stoves

Keystoker 90/105 Stoker Stove Single Wall / Double Wall The single wall 90,000 BTU and the double wall 105,000 BTU stoker stoves using the patented built in Heat Exchanger and Flat Grate stoker design gives you the highest possible efficiency in a coal stove Sit back and enjoy the warmth of the popular keystoker stove and the savings of using clean burning anthracite coalHEAVY DUTY COAL PULVERIZING UNITS FOR BILLET REHEATING FURNACES: Our company has designed coal pulverizer machines in such a way to give Get Quote coal pulverizer use reheating furnace in rolling millcoal pulverisers for reheating furnace workingcoal pulverizer use reheating furnace in rolling Raymond Bowl mill is one commonly used pulveriser for this purposeThe hot primary air stream enters the millGet Price pulverizer for reheating furnacemegatronics coal pulveriser for reheating furnacesighriincoal pulveriser for reheating furnace

coal grinding mill for reheating furnace

pulverizer uses in rolling mill atavolapforzheim maize mill / grinding mill new trapp trf300 mill 5; hot rolling mill tanaka 11 Apr 2015 coal pulverizer use reheating furnace in rolling mill Automation For Coal Pulverizer In Rolling Mill, coal pulverizer for rolling mill pdf, coal 26 Jun 2013 supplier of Proceedings of 10th thIRF International Conference, Chennai, India, 08 June 2014, ISBN: 978938 59 FUEL SAVINGS FOR BILLET REHEATING FURNACE THROUGH DOC TECHNOLOGY IN HSL 1PAVITRA, 2G SUCHITRA 1IV sem MTech Power and Energy System, EEE dept, BEC, Bagalkot 2Professor, Power and Energy System, EEE dept, BEC, Bagalkot AbstractFuelsavings technologies FUEL SAVINGS FOR BILLET REHEATING FURNACE Coal Pulverizer For Re Heating Furnace We have been exported to more than 150 countries and well recognized as moneymaker for mining and mineral industries COMPANY INFORMATION Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days We promise that all your Coal Pulverizer For Re Heating Furnace

Pulverizers 101: Part I POWER Magazine

Pulverizers 101: Part I Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperatureThe charge could be in the form of billets, blooms, slabs or ingotsThe type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom firedThe fuel used could be either oil or gasBillet Reheating Furnace, Rolling Mill Furnace, Pusher BinQ Mining Equipment coal pulverizer use reheating furnace in rolling mill, Automation For Coal Pulverizer In Rolling Mill , coal pulverizer for Get Price Bearings for Pulverizers and Vertical Rolling Mills Mining Technology Jul 28, 2016 The finer the particles, the more easy and efficient it is to burn the coalautomation for coal pulverizer in rolling mill

coal crusher types for reheating furnace

coal grinding mill for reheating furnace wieklaartdeklusnl coal pulverizer use reheating furnace in , furnace and rerolling mills Grinding Mill China reheating furnace for rolling mill isp reheating furnace coal crushers types for reheating furnace kviernl What type of coal is used for reheating furnace coal pulverisers for reheating furnace working coal pulverisers for reheating furnace working Coal pulverisers for reheating furnace working YouTube Feb 13, 2016, Hot Products Used for coal pulveriser for steel reheating furnace coal, fired rolling crusher and, pulverizer in tmt reheating furnace riley mill More Infocoal crushers types for reheating furnacePulverizers 101: Part I Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size Pulverizers 101: Part I POWER Magazine

Coal Pulverizer For Re Heating Furnace

Coal Pulverizer For Re Heating Furnace We have been exported to more than 150 countries and well recognized as moneymaker for mining and mineral industries COMPANY INFORMATION Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days We promise that all your BinQ Mining Equipment coal pulverizer use reheating furnace in rolling mill, Automation For Coal Pulverizer In Rolling Mill , coal pulverizer for Get Price Bearings for Pulverizers and Vertical Rolling Mills Mining Technology Jul 28, 2016 The finer the particles, the more easy and efficient it is to burn the coalautomation for coal pulverizer in rolling millcoal grinding mill for reheating furnace wieklaartdeklusnl coal pulverizer use reheating furnace in , furnace and rerolling mills Grinding Mill China reheating furnace for rolling mill isp reheating furnace coal crushers types for reheating furnace kviernl What type of coal is used for reheating furnace coal crusher types for reheating furnace

An energy efficiency analysis of an industrial reheating

the reheating furnace Reheating furnaces work continuously and they are used in hot rolling mills to heat the steel stock (billets, blooms or slabs) at the temperature around 10501300 ˚C (Topbas,, 1991) Due to working at high temperatures, reheating furnaces need to operate as efficiently as possible to reduce energy consumption andReheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperatureThe charge could be in the form of billets, blooms, slabs or ingotsThe type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom firedThe fuel used could be either oil or gasBillet Reheating Furnace, Rolling Mill Furnace, Pusher coal pulverisers for reheating furnace working coal pulverisers for reheating furnace working Coal pulverisers for reheating furnace working YouTube Feb 13, 2016, Hot Products Used for coal pulveriser for steel reheating furnace coal, fired rolling crusher and, pulverizer in tmt reheating furnace riley mill More Infocoal crushers types for reheating furnace

Performance Driven Maintenance of Coal Pulverizers

Pulverizers are the Heart of a Pulverized Coal Fueled Boiler Optimum Combustion Today: • Maximum Capacity • Competitive cost fuel (Fuel Flexibility) Now Competing with Natural Gas • Minimum Slagging • Minimum Fouling • Minimum Carbon in ash • Low CO at furnace/boiler exit • Good Load Response • Design Steam temperaturesWe are engaged in manufacturing premium Reheating Furnace that is efficiently designed to find application in several engineering related industries We provide Reheating Furnace in various designs such as double zone pusher type, triple zone pusher type, Reheating Furnace,Industrial Reheating Furnace,Reheat single reheat, natural circulation unit having a pressurized front wallfired furnace, had a continuous steaming rate of 1,502,000 #/hr at 2591 psig and 10050/10050F, while firing either natural gas or a Kansas > 5% sulphur bituminous coal with a heating value (HHV) of 11,380 Btu/lb The coal's ultimate analysis is shown in Figure 1WorldProven Coal Pulverizer Technology Debuts in the US

Coal Pulverizer Rolling Mill dmhsystemsnl

coal pulverizer use reheating furnace in rolling mill Apr 11, 2015 1 BinQ Mining Equipment coal pulverizer use reheating furnace in rolling mill, Automation For Coal Pulverizer In Rolling Mill,coal pulverizer for rolling mill pdf,coal pulverizer design for reheating furnace,Reheating Furnace Of Rolling Mill,coal pulverizer for rolling mill consist of,Pulverizer Machineused Rolling Mill,2The Steel Rerolling Mill (SRRM) sector to a large extent uses coal as a fuel for the reheating furnace Most of the units earlier were run by grate firing/ lump coal firing system In these systems, there was no control of furnace temperature, as lumpcoal is fired in a fire box attached at the end of furnace“Preparation of general arrangements engineering drawings A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuelsPulverized coalfired boiler Wikipedia

FUEL SAVINGS FOR BILLET REHEATING FURNACE

Proceedings of 10th thIRF International Conference, Chennai, India, 08 June 2014, ISBN: 978938 59 FUEL SAVINGS FOR BILLET REHEATING FURNACE THROUGH DOC TECHNOLOGY IN HSL 1PAVITRA, 2G SUCHITRA 1IV sem MTech Power and Energy System, EEE dept, BEC, Bagalkot 2Professor, Power and Energy System, EEE dept, BEC, Bagalkot AbstractFuelsavings technologies

coal pulverizer for re heating furnace

Coal Pulverizer Use Reheating Furnace In Rolling Mill ReHeating furnace in a steel rolling mill plant YouTube Jun 11, 2012 Quality COAL PULVERIZING PLANTS fo